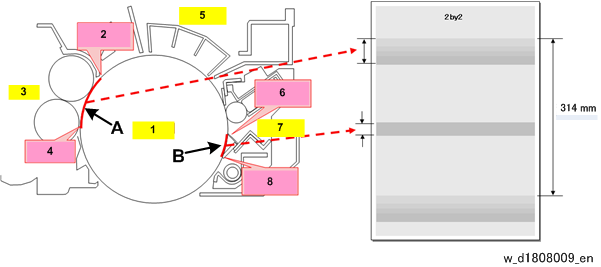

When printing images with halftone fill, uneven density appears at locations where there are open spaces.

1 | Drum |

2 | Development Entrance Seal |

3 | Development Unit |

4 | Development Roller (Lower) |

5 | Charge Unit |

6 | Lubrication Mylar |

7 | Drum Cleaning Unit |

8 | Drum Cleaning Blade |

Cause:

With 2by2 or 4by4 halftone images, the density becomes uneven at the open gaps [A] at the development unit and [B] at the drum cleaning unit.

- Uneven density can appear at the upper and lower position where the image could become partially lighter or darker.

- If differences in temperature and humidity develop between the open and closed spaces around the circumference of the drum (314 mm), this can cause fluctuation in the electrical potential of the drum charge after image exposure and easily create changes in density.

- This problem can easily occur where humidity is low.

Solution

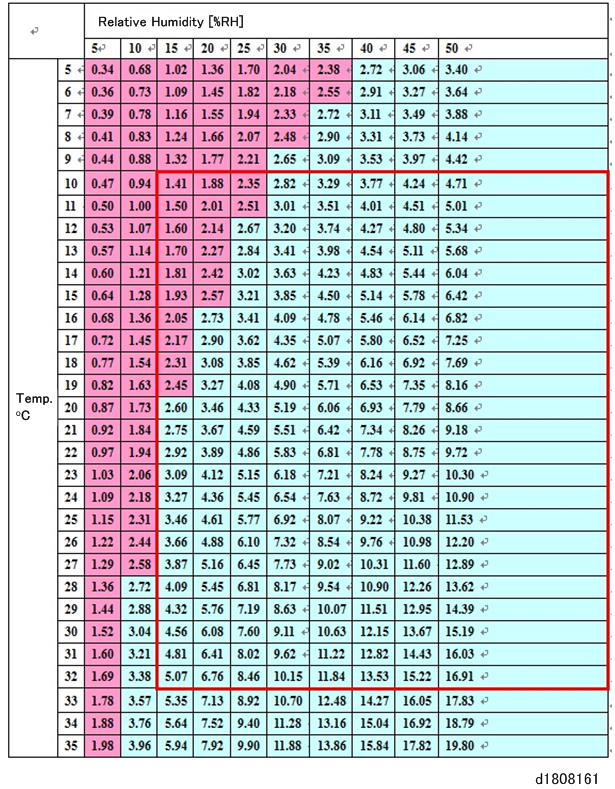

Is the absolute humidity above 2.6? (The absolute humidity in the lookup table below is calculated from the temperature and relative humidity.)

Yes

Consult the product specialist.

No

Go to the next step.

Can the ambient temperature and humidity be adjusted?

Yes

Go to the next step.

No

Consult the product specialist.

- Raise the temperature so that absolute humidity is above 2.6.

- Adjust ambient conditions so that the work site is above 15°C (59°F) 30% rH.

Print the image. Is the problem resolved?

Yes

Finished!

No

Consult the product specialist.

Lookup Table for Calculating Absolute Humidity

Absolute humidity is calculated from ambient temperature and relative humidity based on the lookup table below. The areas within the heavy red line in the table below indicate values where quality is assured. To prevent uneven image density, absolute humidity should be above 2.6 within the red shaded areas.

Units: g/m3

Ab. humidity = 217x (6.11x10(7.5 x temp/ (temp+237.3)))/(temp+273.15) x Relative humidity x 0.01