In the previous machine one motor drives the drum of the PCDU as well as the fusing unit, but in this machine, the drum and fusing unit are driven by separate motors.

This two-motor configuration is designed so the drum and fusing unit do not rotate together, except during printing to lengthen the service life of the PCDU and reduce toner consumption.

This machine employs several operation modes: silent mode, envelope print mode, curl prevention mode, maximum power consumption mode, and others. The table below summarizes the operation of the fusing unit and PCDU in each mode and how this affects the service life of the PCDU.

| Mode | Fusing Drive | OPC Drive | Effect on PCDU Service Life | Machine Operation | |

|---|---|---|---|---|---|

| Normal printing | Idles for about 3 sec. before printing | Driven only during printing | - | - | |

| Silent mode | Idles for about 3 sec. before printing | No effect | Line speed down to 30 ppm | ||

| Envelope print mode | Idles for about 3 sec. before printing | No effect |

| ||

| Thick-3 mode | Idles for about 10 sec. before printing | No effect on idling time; however, the interval between sheets widens when line speed goes down, the drum also goes through many rotations so this has no effect. |

| ||

| Low power CPM mode (200V model only) | Idles for about 10 sec. before printing | ||||

| Curl reduction mode | Thick1-3 | Idles for about 10 sec. before printing | |||

| Misc. | Idles for about 3 sec. before printing |

| |||

| Max. power consumption reduction mode*1 | Idles for about 3 sec. before printing | No effect | To control power, startup time is extended by about 5 sec. | ||

| Punch hole mode*2 | Idles for about 3 sec. before printing | The distance of drum travel between each sheet increases, but it is extremely small and has no effect. | The interval between sheets increases slightly | ||

*1 Maximum power consumption reduction mode

Enabling this mode can lower the maximum power consumption of the machine when the main power supply breaker is tripping due to the use of multiple printers or the power capacity of the installation site is insufficient. For more details, refer to Suppressing Maximum Power Consumption.

*2 Punched hole mode

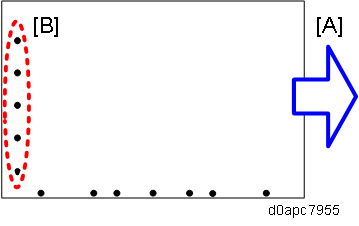

Jamming can occur with paper feeding in the [A] direction with open holes [B] at the trailing edge as shown below. When the paper transport sensor in the optional bank detects the punched hole:

- The paper transport sensor turns OFF at the punch hole. This triggers an incorrect detection of the trailing edge of the paper.

- Next, the paper transport sensor turns ON again after the open hole passes. The machine incorrectly detects this as the leading edge of the next sheet. This interruption in the sequence of normal feed timing causes a paper jam.

To solve this problem:

- Mask control is performed so the paper transport sensor is turned off and will not detect again until the paper has traveled 25 mm past the sensor.

- The machine goes into the punched hole mode automatically when Labels or Thick-3 are selected for the paper type because perforations are common with these paper types frequently used by customers in the healthcare industry.

- In this mode, the paper feed start timing is delayed 25 mm for each sheet, so this slows productivity down slightly to about 29 ppm.