A paper sensor below the stapling slot detects the presence or absence of paper.

- 100 ms after detecting paper, the staple drive motor switches on and the staple operation begins. If no paper is detected within this 100 ms, the staple operation does not begin.

- The sensor that detects the paper is a photosensor so it will not detect the paper when there is no margin on the reverse side of the paper and it is black.

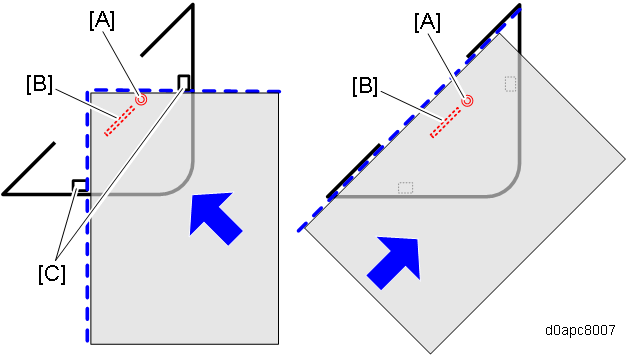

Papers can be stapled diagonal (corner staple) or parallel to the edge of the paper (margin staple), depending on how the papers are inserted into the stapler slot.

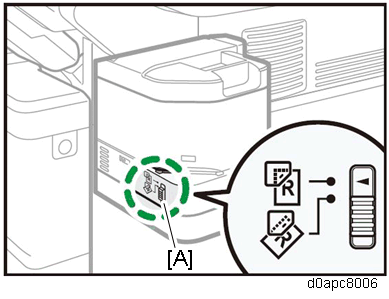

Changing the setting of the slide switch [A] on the front of the stapler unit changes the angle at which a stack can be inserted.

- Raise the slide switch to raise the stoppers, and when the sheets are inserted along the stoppers, the stack can be stapled at the corner with the staple diagonal to the edges of the sheets.

- Lower the slide switch to lower the stoppers, and when the sheets are inserted from the front along the guide inside the stapler, the stack can be stapled in the margin with the staple parallel to the edges of the sheet.

[A] Paper sensor exposure position

[B] Staple position

[C] Stoppers

Precautions During Use

- During repeated use, wait more than 3 sec. between stapling.

- When using the stapler never turn the main machine off or set it in the Energy Save Mode. This will cause the machine to stop, the stack may jam in the stapler and you will not be able to remove it.

- If paper becomes jammed in the stapler, remove the staple unit from its mount, set it on the machine again and turn on the machine. This will re-initialize stapler and you will be able to remove the jammed stack.

- The staple cartridge is removed by lifting, not pressing down, so if the cartridge is struck and disconnected, the staples past the point of disconnection cannot be lifted out. If this occurs the staple cartridge must be replaced.