Paper Feeding

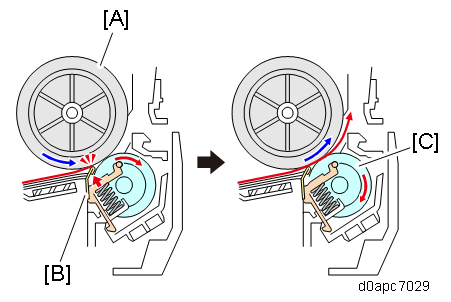

The paper feed tray of the main machine employs the RF (Roller Friction) method for paper separation. The RF mechanism comprises a separation roller with a torque limiter attached that forces paper separation (no reverse drive is used).

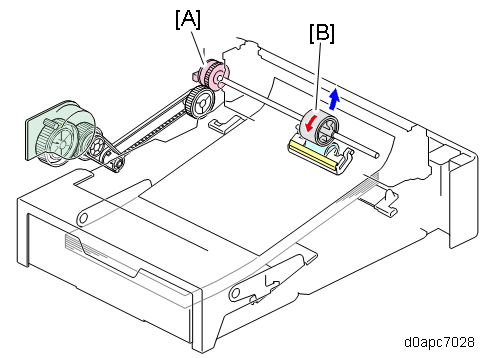

A paper feed signal switches on the paper feed clutch (CL6) [A] and starts rotating the feed roller [B] which feeds the paper. When the leading edge of the moving paper switches on the registration sensor (S5), this switches the feed clutch off. Image position timing starts while the registration sensor (S5) is on, and then the paper is transported to the transfer unit.

In front of the feed roller [A] a pre-separation plate [B] is installed to block the top of the stack from entering past the feed roller. The friction roller [C] separates the first sheet from the top of the stack so only the top sheet feeds.

Paper Feed Retry Control

In the main machine if the sheet does not feed after the paper feed signal is issued, the machine will issue another paper feed signal and try once more to feed the paper it issues a jam error. If the next attempt fails, the machine will issue a jam error. The machine is set to make one retry by default, but the number of attempts to retry paper feed can be adjusted for each paper tray with the SP codes (0, 1, or 2 retries) listed below.

| SP No. | SP name |

|---|---|

| SP1-909-001 | FeedRetryCount: Manual Feed Tray |

| SP1-909-002 | FeedRetryCount: Tray1 |

| SP1-909-003 | FeedRetryCount: Tray2 |

| SP1-909-004 | FeedRetryCount: Tray3 |

| SP1-909-005 | FeedRetryCount: Tray4 |

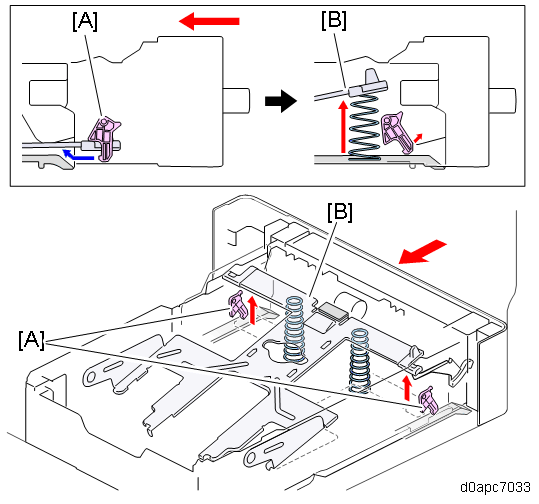

Bottom Plate Lift Mechanism

When a paper tray is set in the machine, a catch on the frame of the machine snags the bottom plate lock lever [A] and releases it. When the lock is released, a spring raises the bottom plate [B] and paper stack to the feed roller.

Also, the bottom plate and end fence are linked, so when the bottom tray rises, the end fence shifts forward against the trailing edge of the stack. This keeps the edge of the stack against the fence to prevent misfeeds.

Improved Handling of Registration Roller Jams

Raising the registration guide (the transparent roller cover) slightly raises the registration roller mechanism. This allows easier removal of paper jams at the registration roller.

Output of Different Size Paper

In this machine, if the paper size setting and length of the paper feeding are not the same, the paper will immediately eject without printing to avoid causing a paper jam. The machine displays an alert on the operation panel so the operator can cancel the print job and start again with the correct paper size and paper size setting.