This machine employs a PID controller to modulate the fusing temperature.

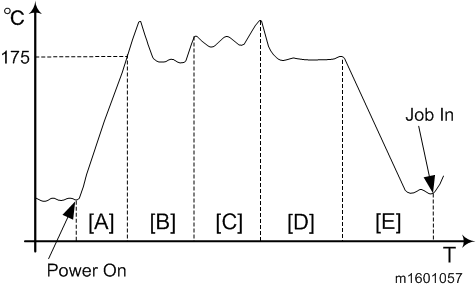

When the machine is turned on, the fusing lamps turn on and remain on until the hot roller reaches pre-rotation temperature. Next, the hot roller rotates to heat its surface evenly to raise the fusing temperature to the reload temperature.

The fusing lamps remain on while the fusing thermopile (TH2) monitors the temperature of the hot roller at the center of the fusing unit, and the fusing thermistor (TH1) monitors temperature at the end of the hot roller. The fusing lamps remain on until both detect Standby Mode [B].

The fusing lamps continue to alternately switch off and on to maintain the standby temperature. At the start of printing, the temperature is increased to Print Mode [C]. After a print job, the hot roller continues to rotate (pre-rotation) to prevent overshooting after printing.

[A]: Warming Up Mode

[B]: Standby Mode

[C]: Print Mode

[D]: Standby Mode

[E]: Energy Saver Mod

Here is a list of target temperatures for each print mode in optimal ambient conditions. These temperatures are adjusted automatically in low-temperature environments.

Status | Target temperature (Center) °C | Target temperature (End) °C | |

|---|---|---|---|

Standby Mode | 163 | 158 | |

Print Mode | Plain paper 1 | 170 | 165 |

| Plain paper 2 | 178 | 173 | |

Middle Thick | 186 | 181 | |

Thick Paper 1 | 198 | 193 | |

Thick Paper 2 | 185 | 180 | |

| Thick Paper 3 | 164 | 159 | |

Thin Paper | 139 | 134 | |

Envelopes | 205 | 205 | |

| OHP | 198 | 193 | |

Post Cards | 205 | 200 | |

The fusing temperature, except for that of the Energy Saver mode, can be adjusted in the SP mode (SP1-105).