Image Transfer

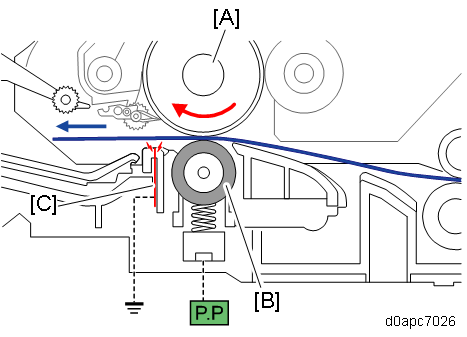

After passing through the registration unit, the paper passes between the OPC drum [A] and the transfer roller [B]. During this time, the toner on the OPC drum surface is transferred to the paper by the positive electric charge on the transfer roller.

The voltage is applied to the transfer roller from the HVPS through receptacles, electrode terminals, a transfer roller spring, and bearings made of conductive resin composite.

Transfer current is adjusted for paper trays (paper feed unit, bypass tray, duplex tray) for paper size, paper type, the number of sheets, and for ambient conditions (operating environment). Further, the output voltage is checked when the transfer current is applied.

If the output voltage exceeds the prescribed voltage, the current is adjusted (corrected), and then feedback control achieves the target voltage.

Paper Separation

The paper separates from the OPC drum because of the curvature of the OPC drum [A] and because of the grounded discharge plate [C] downstream of the transfer roller [B]. Irregularities in the toner image at the time of separation are prevented by an electric field.