This machine is provided with a new fusing pressure/release motor (M2) which controls the opening and closing of the nip between the hot roller and pressure roller.

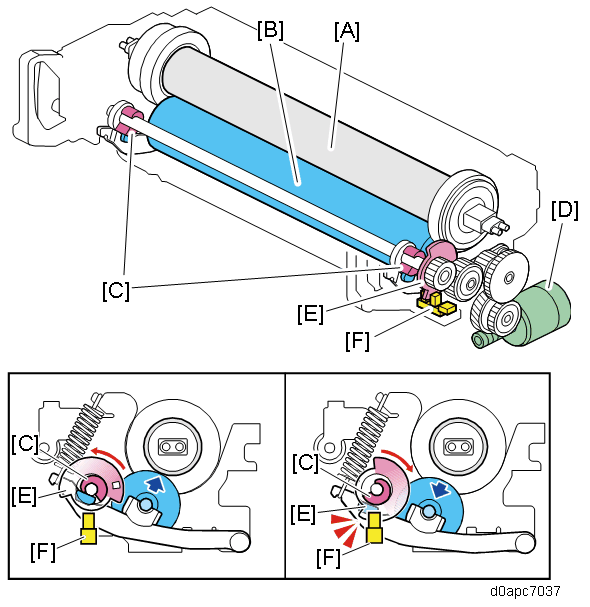

The hot roller [A] and pressure roller [B] are pressed together by two large springs. The lift cam [C] is provided to shift the position of the pressure lever against the springs to maintain the pressure. Fusing pressure/release motor (M2) [D] rotates a series of gears which in turn rotates the lift cam against the lift lever which raises and lowers the pressure roller.

Attached cam feeler [E] rotates, while the fusing nip pressure position sensor (S7) [F] (installed at the rear) monitors the status at the gap.

The pressure is released if a paper jam occurs, making it easier to remove the jammed paper. Pressure is released when the machine is off, or in standby mode, to prevent warping the shape of the pressure roller.

| Machine status | Pressure status | |

|---|---|---|

| Startup | Power on, warm up | Released |

| Rotations after reloading temperature cycle | Applied | |

| Printing | Print job other than envelopes | Applied |

| Envelope print job | Released | |

| Standby | Released | |

| Abnormal halt | Released | |