Paper may tear at the leading edges of paper if paper with residual burrs from cuttings is used. This can also cause double feeds or edges of the sheets to stick together.

Cause

Burrs caught on the edges of paper when stacks are cut during manufacturing can cause the trailing edges of the paper stick to the leading edges of the following sheets and lead to double-feeds or continuous feeds with the trailing and leading edges sticking together.

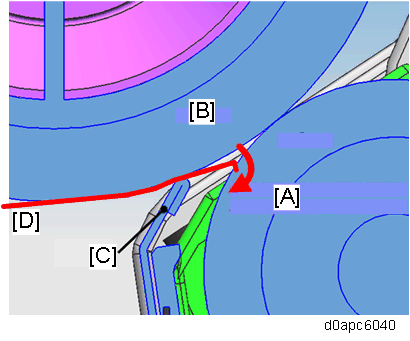

During paper separation, if there are burrs on the leading edges, the contact between the separation roller and leading edges can cause tearing at the leading edges. (See diagram below.)

Condition with cutting burrs over 0.1 mm high

[A] Separation roller

[B] Feed roller

[C] Pre-separation plate

[D] Paper

Solution

Do the following for the paper being used.

- Change the position of the paper stack.

A. Swap the front and back of the stack (leading edge and the trailing edge in the direction of feed).

B. Turn the stack over (without changing the direction of feed).

C. If Step A, B does not solve the problem turn the stack over and change the direction of feed. - Confirm that there is no moisture in the stack.

Request the operator to use paper that has been stored at acceptable range of temperature and humidity. You can also set the machine in curl reduction mode. - Check to see that the paper is a type not recommended for use with the machine.

Request the operator to use only paper that is recommended for use with the machine. - Make sure that the paper stack is not over the load limit for the paper feed tray.

Set a stack of paper so it does not exceed the limit for the side fence of the paper feed tray.

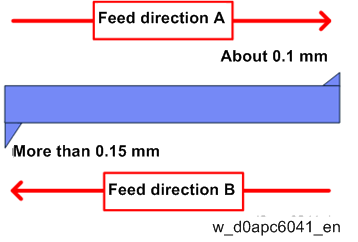

However, as shown in the figure below, for paper types whose trimming burrs are reversed at the leading edge of the paper and at the trailing edge of the paper, even if the paper is inverted with respect to the direction of feeding, there are cases where these methods are not effective.

- In paper feed direction A, small catching at the separation roller causes a small edge tearing.

- In paper feed direction B, a large incidence of catching at the separation roller causes a large amount of edge tearing.