Paper Feed and Bottom Plate Operation

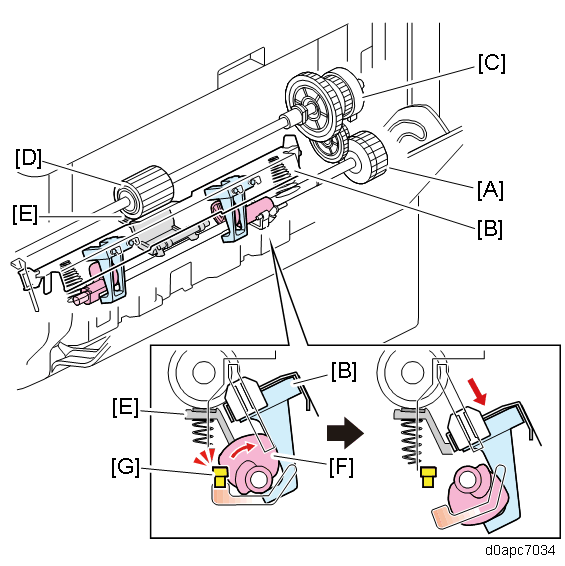

When the paper feed signal is issued for the bypass tray, the bypass lift clutch (CL3) [A] starts to rotate and raises the bottom plate [B].

Next, the bypass feed clutch (CL4) [C] switches on and rotates the bypass feed roller [D]. At the top of the paper stack in the bypass tray, the top sheet separates at the friction pad [E] and feeds into the machine toward the registration roller.

When the leading edge of the paper turns on the registration sensor (S5), this switches the bypass feed clutch (CL4) off. Image position timing takes over and positions the paper for image transfer. The registration clutch (CL5) switches on and the paper feeds to the transfer unit.

The bypass tray bottom plate [B] is raised and lowered by the cam [F] attached to the shaft rotated by the bypass lift clutch. The friction pad [E] is linked to the bottom tray so it also rises to maintain contact with the bypass feed roller to effect paper separation at the top of the stack. The feeler of the bypass tray sensor (S3) [G] attached to the cam switches on and off to detect the position of the tray as it moves up and down.

- ON (sensor gap open): Bottom plate down

- OFF (sensor gap blocked): Bottom plate up