This model uses a conventional mechanism in which paper comes in contact with the exposure glass during feeding. This is useful for dealing with adhesion of free dirt particles (paper scraps, etc.). (Self-cleaning mechanism using paper)

On the other hand, dirt adhering to the original can stick to the exposure glass and cause black lines in the scanned images

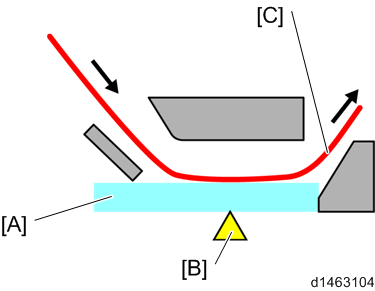

SPDF cross-section diagram

[A]: Exposure glass

[B]: Reading position

[C]: Original feed path

Read Position Correction

By changing SP4-020-001 (Dust Check: Dust Detect: On/Off), when dirt is detected at the reading position, the reading position may be changed to avoid the dirt.

(If it cannot be avoided, an alert is displayed on the operation panel advising the user to clean the exposure glass).

The scanning position can be corrected even for originals with dirt on the reverse side by switching SP4-020-011 (Dust Check: Dust Detect Level: Rear).

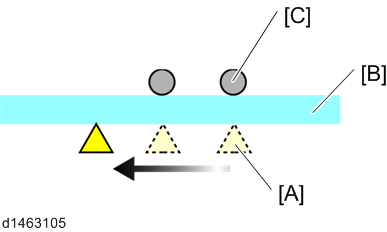

Image diagram

[A]: Reading position

[B]: Exposure glass

[C]: Dirt

- Dirt is detected when a document passes through, so the alert will not disappear until the reading of the next document begins, even after exposure glass cleaning is performed.

- If dirt is detected not on the exposure glass but on the background guide plate, the alert will not disappear even if the glass is wiped clean.

- The time required for the first copy is slightly (almost imperceptibly) longer.

- The detection threshold can be changed using SP4-020-002 (Dust Check: Dust Detect:Lvl). The larger the value, the smaller the dirt particles that can be detected.

- Do not change the setting of SP4-020-003 (Dust Check: Dust Reject:Lvl).