- Make sure that you have the SMC report (Factory SP Settings). This report comes with the machine.

If you do not have the SMC report, enter the factory settings while referring to the "Factory SP Settings". - Output the SMC data ("ALL") using SP5-990-001/SP5-992-001.

- Turn OFF the main power and unplug the power cord.

Replace the NVRAM on the IOB (PCB17) with a new one.

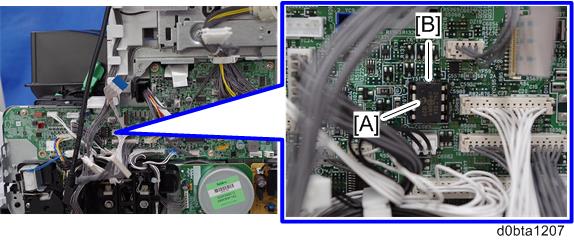

- Install an NVRAM [A] so that the indentation [B] on the NVRAM corresponds with the mark on the IOB (PCB17). Incorrect installation of the NVRAM will damage both the IOB (PCB17) and NVRAM.

- Install an NVRAM [A] so that the indentation [B] on the NVRAM corresponds with the mark on the IOB (PCB17). Incorrect installation of the NVRAM will damage both the IOB (PCB17) and NVRAM.

Plug in the power cord, and then turn ON the main power.

Execute SP5-901-00x "All Data Initialize".

Destination SP AA SP5-901-008 NA/LA (120 V) SP5-901-007 EU/LA (230 V) SP5-901-006

Do not use SP5-901-009 (Oceania).

- Turn OFF the main power, then turn ON the main power again.

Set SP4-698-003 “Factory mode” to “1”.

- Do not open the front cover, and do not turn OFF/ON the main power until step 11.

- For information on how to configure the above SP, contact the supervisor in your branch office.

- The displayed number will be changed to “0” soon after setting SP4-698-003 to “1”. This is normal operation and the SP has been executed correctly.

- Execute SP3-900-002 “Toner Install Mode: Off”.

- Set the below SPs to see the SMC report (Factory SP Settings) from step 1 or 2.

- SP4-108-001 “Sub Scan Speed Adjustment”,

- SP4-110-001 “L-Edge Timing Adjustment”,

- SP6-026-001 “ADF Timing Adjustment, Leading Edge Start Timing: Front”,

- SP6-027-001 “ADF Adjustment Scan Speed, Simplex Mode”

- Turn OFF the main power, then turn ON the main power again.

Check the SMC report (Factory SP Settings) from step 1 or 2, and set the user tool and SP settings so they are the same as before.

Check the below SPs have correct values.

- SP6-026-003: 0

- SP6-026-004: 0

- SP6-027-002: -0.3