When the stapled prints are not aligned adequately, it may be because the finisher side-to-side registration is inaccurate. Adjust the finisher side-to-side registration in the following way.

- Enter SP mode.

- Set SP6-138-001 to "1" (default: 0).

This configures the machine to stop the fed sheet at the finisher entrance. - Execute a print job using A4 or LT paper with the finisher selected as the paper output tray.

The printed sheet stops at the finisher entrance. - Remove the right upper cover. (Right Upper Cover (IM 600SRF))

- Remove the left upper cover. (Left Upper Cover (IM 550F/600F))

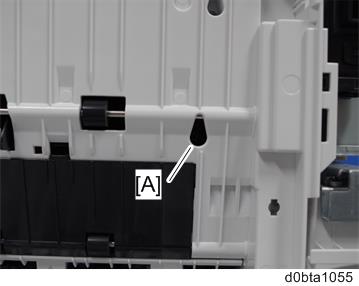

- Open the rear upper cover [A].

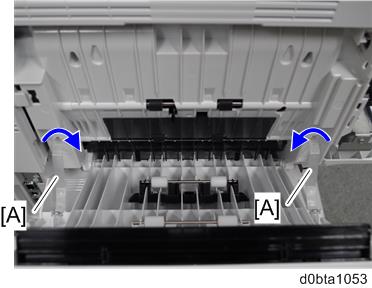

- Release the belts [A] from the mainframe by twisting the ends.

Remove the rear fan cover. (Rear Fan Cover (IM 600SRF Only))

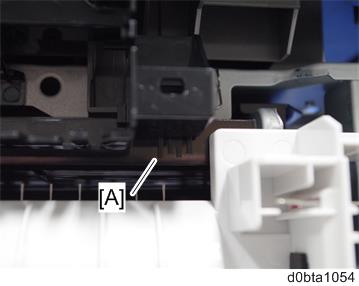

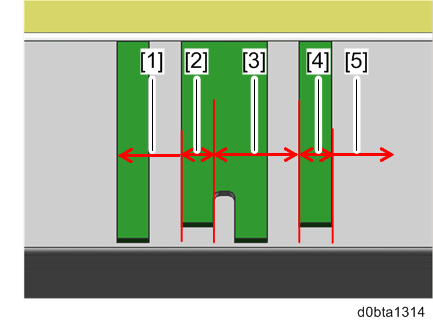

Compare the edge of the paper and the guidelines [A] to determine the required amount of adjustment.

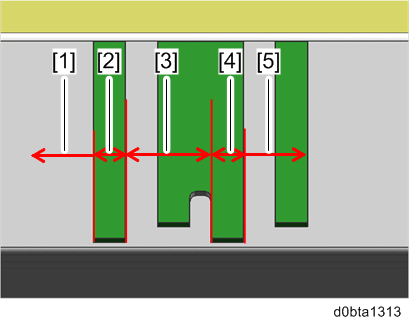

When using A4 sheet When using LT sheet

[1] Move the finisher to the right by 3 mm.

[2] Move the finisher to the right by 1.5 mm.

[3] No adjustment required.

[4] Move the finisher to the left by 1.5 mm.

[5] Move the finisher to the left by 3 mm.

* "Left" and "right" indicate the directions when seen from the front of the machine.

See below for how to determine the finisher position.

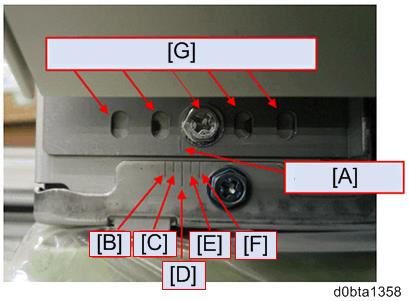

- Align the line [A] with one of the lines that matches the required distance.

[B]: 3 mm to the left

[C]: 1.5 mm to the left

[D]: Center position

[E]: 1.5 mm to the right

[F]: 3 mm to the right - Insert the screw to one of the five slits [G] which is aligned with a screw hole.

- Align the line [A] with one of the lines that matches the required distance.

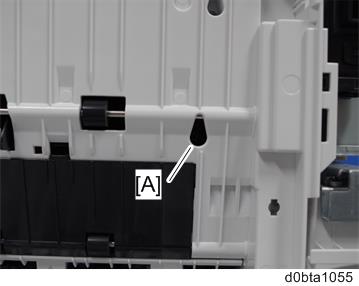

Put a screwdriver through the hole [A] and loosen the screw that fixes the finisher.

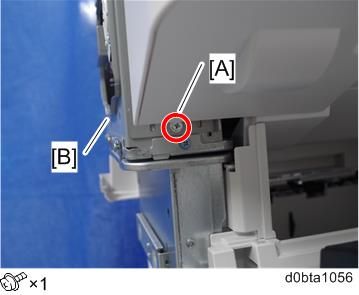

Remove the screw and slide the finisher [A] to the left or right according to the explanation in step 7.

After moving the finisher, reattach the screw in a new position according to the explanation in step 7.

Put a screwdriver through the hole [A] and retighten the screw to fix the finisher.