Turn OFF the machine and disconnect the machine power cord before you do this procedure.

The shipping plates prevent the staple unit from moving during transport. The plates should be kept and re-attached before the unit is transported to another location.

Remove all tapes and retainers from the external covers.

Remove the retainers as shown below.

- Open the front door [A], and then remove the tapes from the upper part of the stacker/stapler unit [B].

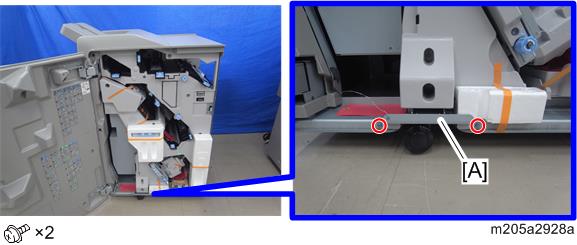

- Remove the shipping plate [A] at the bottom.

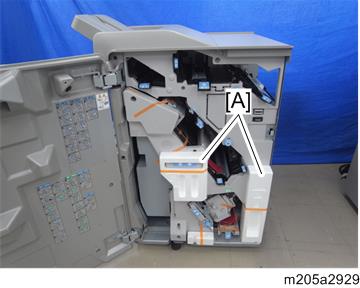

- Remove the retainers [A].

- Loosen the screws [A] of the caster cover.

When the casters [B] touch the floor, tighten the screws of the caster table.

This step relieves stress on the rails of the stacker/stapler unit when it is pulled out of the machine. If the casters come off the floor after the height adjustment of finisher, adjust the height of caster. Otherwise, the guide rail might be strained when you pull out the stacker/stapler unit.

Hold the grip [A], and then pull out the stacker/stapler unit [B].

When pulling out the stacker/stapler unit, remove the retainer [A].

Remove the retainer (shoulder screw) [A].

If you turn on the machine while the shoulder screw is attached, an SC error occurs. Remove the shoulder screw with tag and wire.

- Remove the shipping plate [A].

Remove the screw [A], and then remove the shipping plate [B].

Do not loosen the shoulder screw [C], because it is fastened with a loosening preventer to prevent the screw from becoming loose. The shipping plate [B] is stuck to the screw [C], but the shipping plate [B] can be removed without removing the screw [C].

- Remove the shipping plate [A].

- Remove the retainers [A] and tapes [B] from the left side of the stacker/stapler unit.

- Remove the tape and retainers left on the stacker/stapler unit [A].

- Put the stacker/stapler unit back into the machine, and then remove the tapes from the staple waste box [A].

- At the rear, remove tape from the power cord.