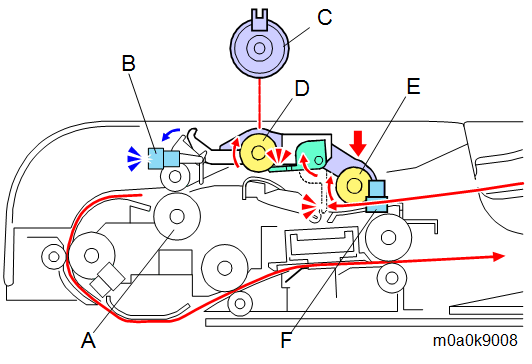

When [Start] is pressed, the feed roller clutch is turned ON. Then the feed roller [A] rotates to drop the pick-up roller [B] onto the top original of the stack. This moves the stopper [E] out of the way, and the original can be fed from the feed roller [A] to the SPDF entrance roller [C].

The friction pad [D] ensures that only one sheet of the original enters the feeder at a time.

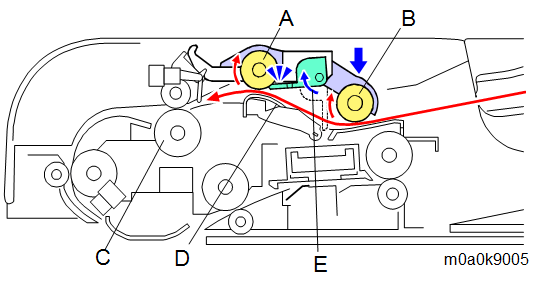

When the original reaches the pre-scanning (front side) roller [B] via the SPDF entrance roller, the original moves the feed sensor actuator [C] and the feed sensor [D] is turned ON. Then the feed roller clutch [E] is turned OFF to stop the feed roller [F] and the pick-up roller [G], to prevent the next original from being picked up.

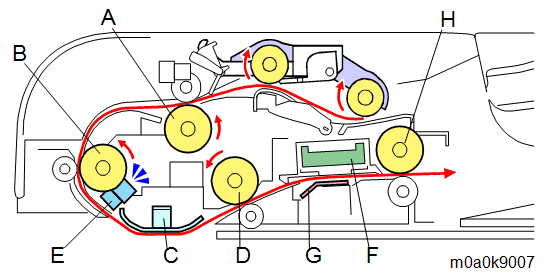

The original is fed by the SPDF entrance roller [A] and the pre-scanning (front side) roller [B], scanned on the exposure glass under the scanning guide plate (front side) [C], and then delivered by the pre-scanning (rear side) roller [D].

The feeding of the original is detected by transport sensor [E]. If an error occurs, it is reported as a paper jam.

The original is fed by the pre-scanning (rear side) roller [D], scanned by the SPDF CIS [F] on the scanning guide plate (rear side) [G], and then fed out by the exit roller [H].

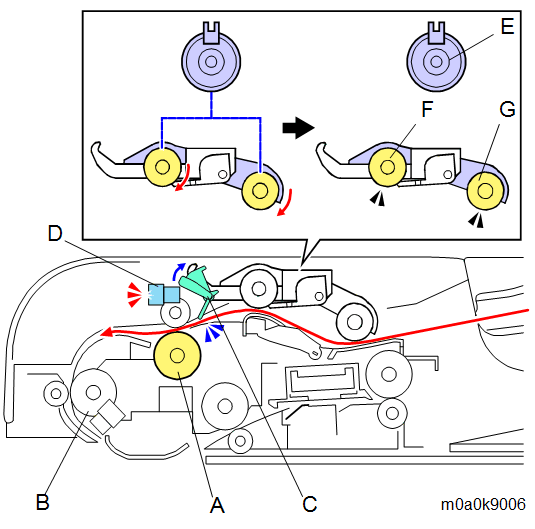

When the original passes through the SPDF entrance roller [A], the feed sensor [B] is detected OFF. If the next original is set, the original set sensor [F] detects ON and the feed roller clutch [C] is turned ON. Then, the feed roller [D] and pick-up roller [E] rotate to pick up the next original.