Image Transfer

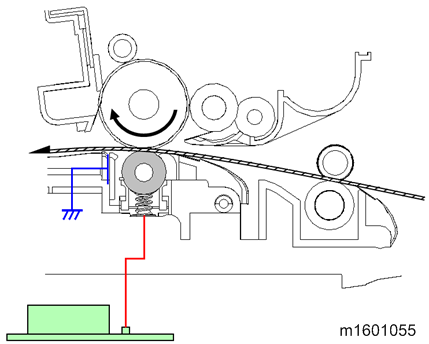

After passing through the registration unit, the paper passes between the OPC drum and the transfer roller. During this time, the toner on the OPC drum surface is transferred to the paper by the positive electric charge on the transfer roller.

The voltage is applied to the transfer roller from the PSU via receptacles, electrode terminals, transfer roller spring (at the front) and bearings (conductive resin).

To minimize fluctuations caused by factors such as the environment and paper types, constant current control is performed.

The transfer current is adjusted in accordance with the paper tray (paper feed unit, bypass tray, and duplex tray), paper size, paper type, and print number of sheets.

- You can adjust these levels (SP2-301 T bias control).

- Increasing the transfer current may produce ghost images–part of the image near the leading edge reappears on another part of the page.

- Increasing the transfer current might damage the OPC drum.

Paper Separation

The paper separates from the OPC drum because of the curvature of the OPC drum and because of the grounded discharge plate downstream of the transfer roller. Irregularities in the toner image at the time of separation are prevented by an electric field.