Drive

The main motor drives PCDU through a coupling.

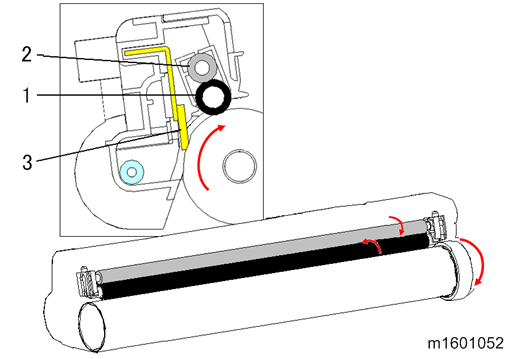

Development

The development mechanism contains the development roller [1], the toner supply roller [2], and the development blade [3]. The toner supply roller [2] provides the development roller [1] with toner. The electrostatic latent image on the surface of the PCDU takes on toner and turns into a visible toner image. The development blade [3] ensures that the toner is applied to the development roller [1] with even thickness.

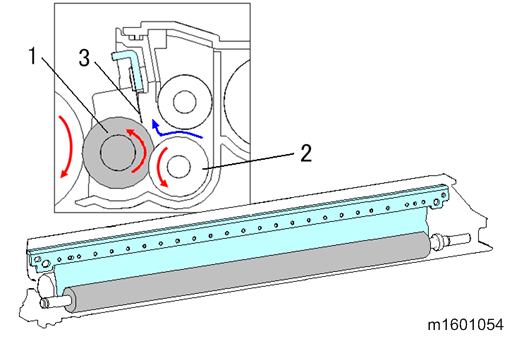

Charge, Charge Roller Cleaning, OPC Cleaning

To prevent ozone from being generated, the machine has a charge roller [1].

The charge roller [1] rotates with the OPC drum to apply an electric charge evenly to the drum surface. However, if the charge roller [1] is dirty, the applied electric charge becomes uneven. Therefore, the charge roller is always in contact with the charge cleaning roller [2], which cleans the charge roller.

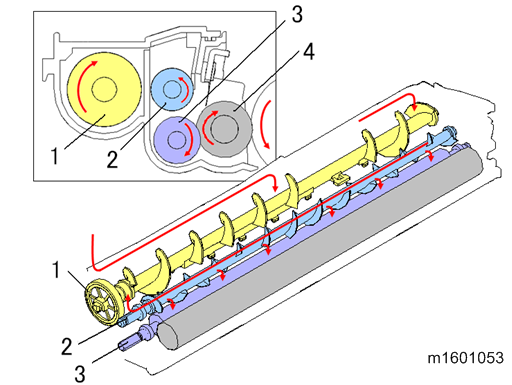

Toner Mixing

The toner moves as shown in the following drawing. The 1st mixing coil [1] moves the toner to the right side. The 2nd mixing coil [2] moves toner to the left side. Finally, the toner supply roller [3] supplies toner to the development roller [4]. By mixing the toner, the toner is circulated and evenly spread.

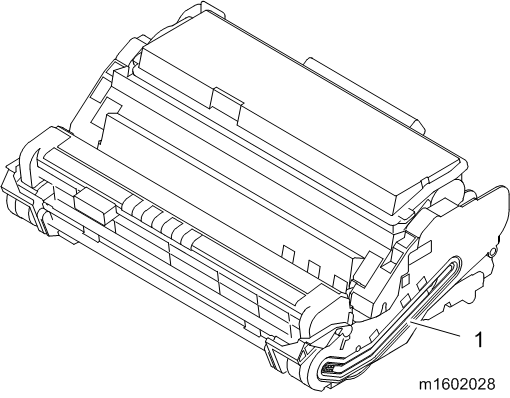

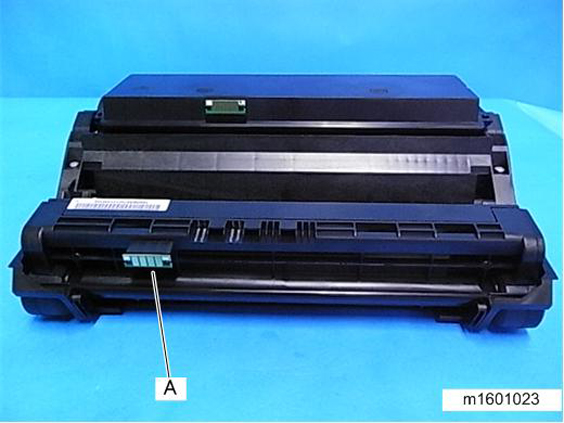

New PCDU Detection, and Set Detection

When a PCDU is placed in the machine, the ID chip [A] is read. In this way, the machine detects when a new PCDU is inserted.

Used Toner Transport

Used toner is collected from the PCDU by the waste toner collection coil and transferred via the used toner transport path [1] on the side of the PCDU to the toner cartridge’s used toner collection box.