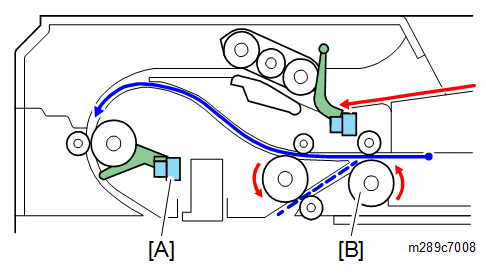

Front Side

When an original is placed on the original tray correctly, the original set sensor actuator is pushed up and the original set sensor [A] turns off (not interrupted). The machine judges this state as the placement of an original. When [Start] is pressed, the ARDF motor rotates the pick-up roller and the feed roller, and the original can be fed. When [Start] is pressed while the machine has not judged that an original was placed, scanning starts and then copying.

The image information is scanned on the sheet-through glass and the original is ejected by the transport roller and the original exit roller.

After starting paper feeding, if the ARDF feed sensor [B] does not detect paper after this sequence, the machine determines that an original jam has occurred.

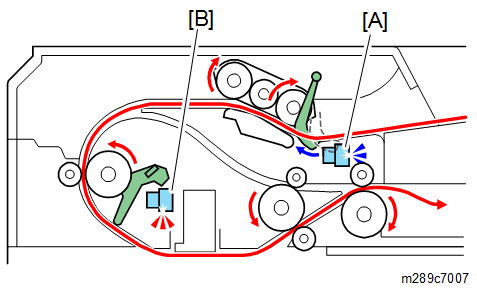

Back Side

After a certain time passes since the original reached the ARDF feed sensor [A], the original exit roller [B] is reversed and the back side of the original is fed. There is no switching mechanism such as a junction gate; the original is delivered to the duplex scanning path by the curved surface of the paper path.

The image information of the back side is scanned on the sheet-through glass and the original is ejected by the transport roller.