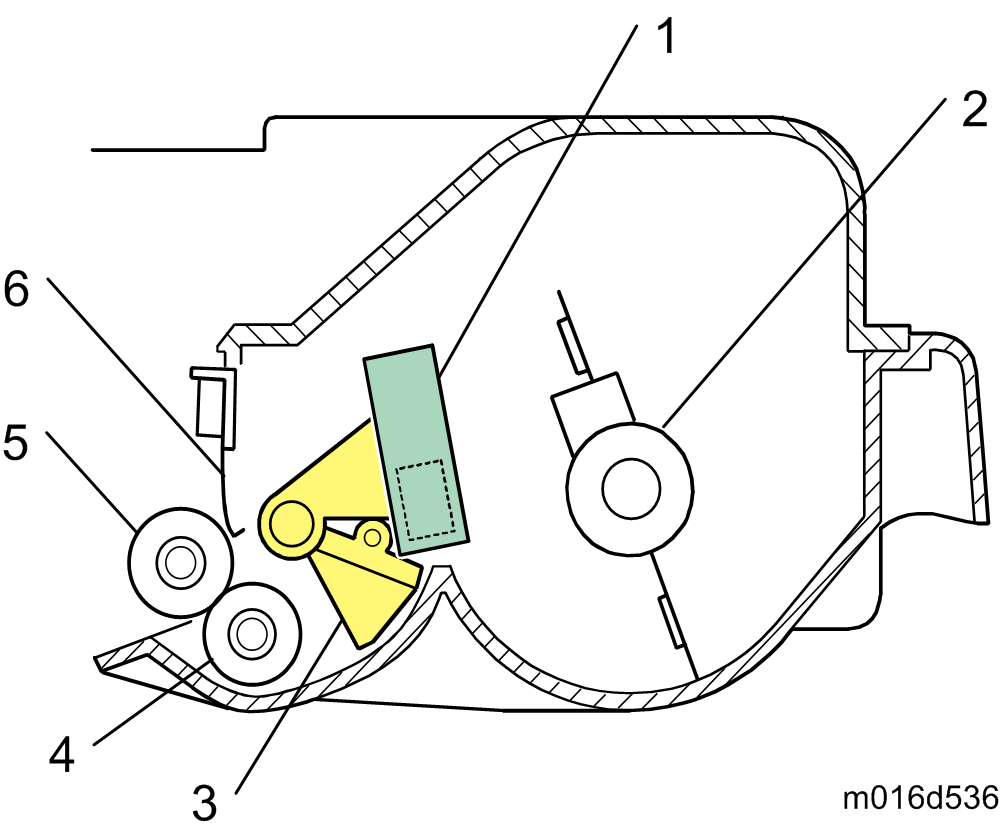

| No. | Item |

|---|---|

| 1. | Toner end sensor |

| 2. | Agitator |

| 3. | Toner detection feeler |

| 4. | Toner supply roller |

| 5. | Development roller |

| 6. | Scraper |

Toner end sensor

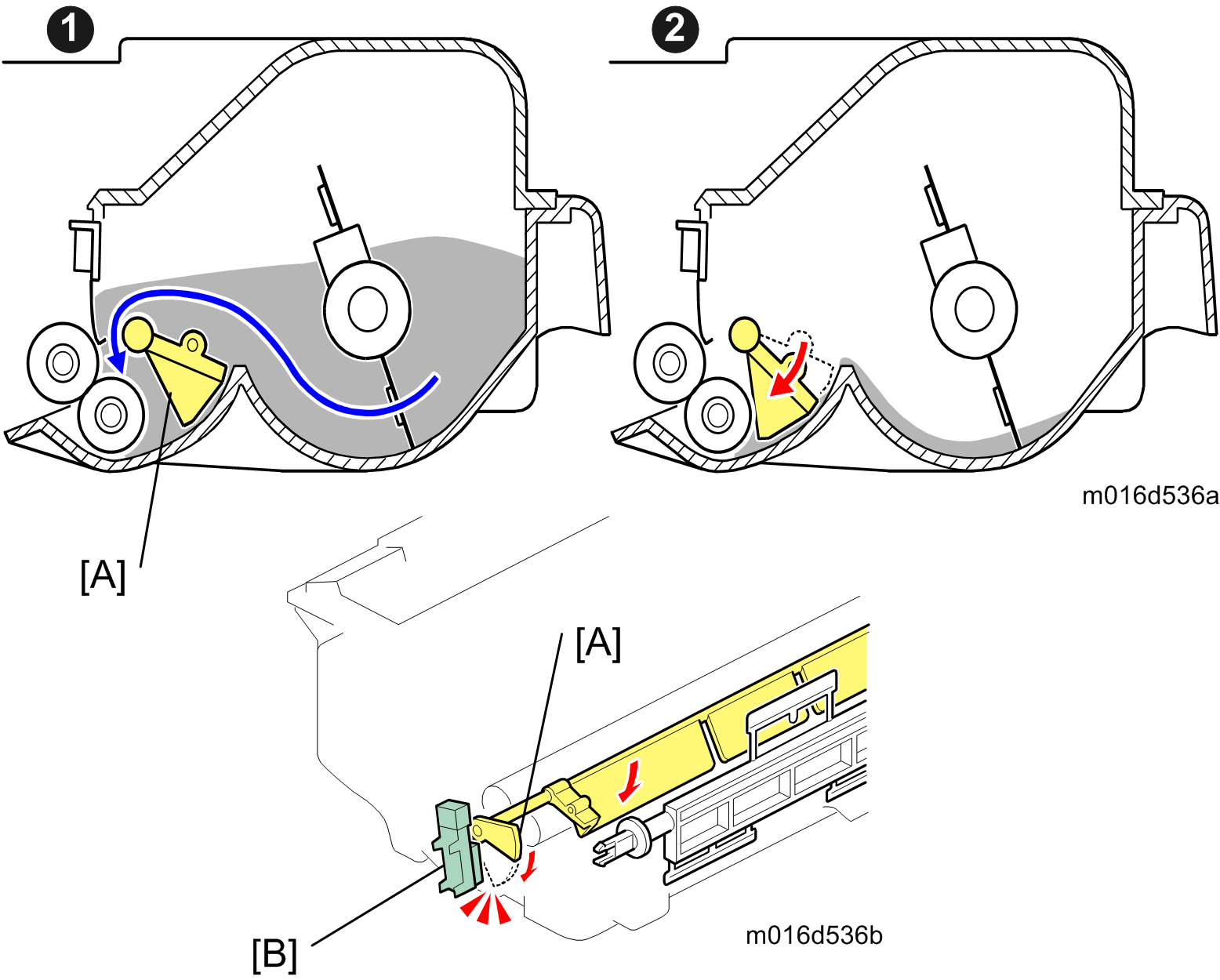

The agitator mixes toner and sends it to the toner supply roller and development roller as shown above [1]. The toner detection feeler comes down when the toner tank is out of toner as shown [2], and then the toner end sensor [B] detects toner end.

The toner end sensor detects toner end by the voltage output. When the output from the toner end sensor is below a given level, the machine displays “Replace Required Soon: Print Cartridge”.

After the additional pages have printed, printing stops and then the “Replacement Required: Print Cartridge” message remains on the display.

Main Motor Rotation Count

The time to replace the AIO cartridge can also be determined by the length of time the main motor has been rotating.

When toner end is detected, “Replacement Required: Print Cartridge” is displayed alternately with ‘Ready’.

Toner Overflow Prevention

With the main motor rotation count feature, the machine can be set to stop printing after the print total exceeds a certain set value. If the print count exceeds this value, then “Replacement Required: Print Cartridge” remains in the display. Then a new AIO cartridge must be installed.

This feature is a safety measure to prevent the used toner tank from becoming full (there is no toner overflow detection mechanism).

Why do we need this feature?

Normally, the AIO is replaced by the user. But some users will refill the old AIO with toner, and use the same AIO again. If this occurs, the used toner tank will not be emptied. So there must be a way to stop users from repeatedly filling the old AIO with fresh toner.

How does the machine know if the AIO is a new one?

The AIO has serial number information on a chip. The machine checks this number when the AIO is placed in the machine.