Transfer/Separation

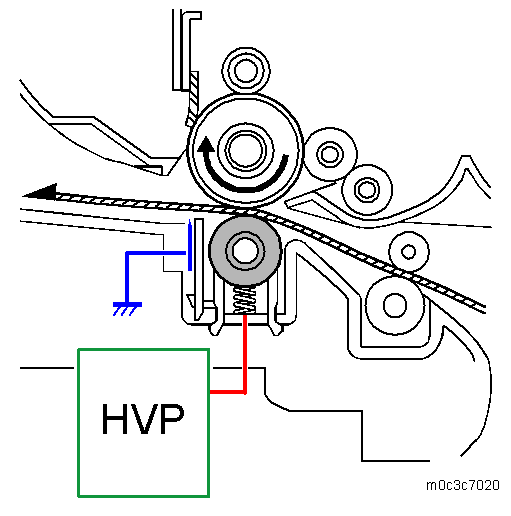

The transfer roller is pressed against the OPC drum. The HVP supplies a positive current to the transfer roller, attracting the toner from the drum onto the paper. The current is set in accordance with the paper's type, size, and feed tray.

Separation of the paper from the drum is aided by the drum's own curvature and by a high AC voltage applied to the discharge plate.

You can adjust the transfer current levels with “Trans. Roller Bias” in the SP Mode (Engine Maintenance). When increasing a transfer current level, use caution:

- Increasing a transfer current level may produce ghost images–some part of the image near the leading edge reappears in another part of the page.

- Increasing a transfer current level might damage the OPC drum.

Transfer Roller Cleaning

Toner may transfer to the roller surface following a paper jam or if the paper is smaller than the image. Periodic cleaning of the roller is required to prevent this toner from migrating back to the rear of new printouts.

The machine cleans the roller at the following times:

- At the end of a job, if at least 10 sheets have been printed since the last cleaning

- After initial power on

- After clearing of a copy jam

The HVP first supplies a negative cleaning current to the transfer roller, causing negatively charged toner on the roller to move back to the drum. It then applies a positive cleaning current to the roller, causing any positively charged toner to migrate back to the drum.