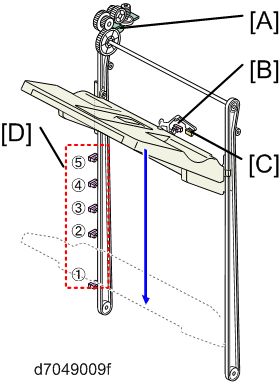

Upper Tray Shift Up/down

The upper tray lift motor [A] moves the upper tray up/down.

Upper-position Detection

With the actuator, the shift paper height sensor [B] detects the upper position of the tray (without output paper). The upper tray height limit switch [C] prevents the tray from moving up too much. When the upper tray moves up to the upper position but doesn’t stop, the upper tray height limit switch is pushed and the tray shift motor [A] stops.

Upper Tray Full Detection

Condition 1

There are five tray full sensors [D] on the rear side of the machine, but Shift Tray Lower Limit Sensor 2 and 4 are not used for this finisher.

State | Sensors | Paper Size | Length |

|---|---|---|---|

500 sheets | Shift Tray Lower Limit Sensor 5 | A5 SEF, A5 LEF, B6 SEF, HLT SEF, A6 SEF | 148 to 182 mm |

| 1,000 sheet | Shift Tray Lower Limit Sensor 4 | Not used for this finisher. | |

1,500 sheets | Shift Tray Lower Limit Sensor 3 | A3 SEF, A4 SEF, B4 SEF, B5 SEF, B5 LEF, DLT SEF, LG SEF, LT SEF, 12"x18" SEF, SRA3 SEF, 13"x19.2" SEF | 182 to 488 mm |

| 2,000 sheets | Shift Tray Lower Limit Sensor 2 | Not used for this finisher. | |

3,000 sheets | Shift Tray Lower Limit Sensor 1 | A4 LEF, LT LEF |

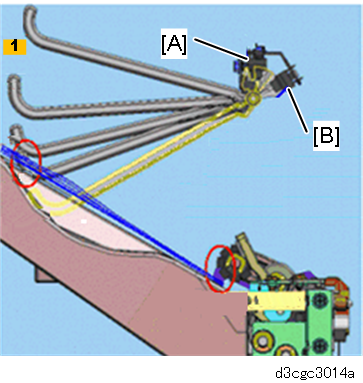

Condition 2

When the feeler rises up to position "1", The booklet stack height sensor 1 [A] is "OFF" and the booklet stack height sensor 2 [B] is "ON".

If this feeler remains in position "1" for 13 seconds continuously, the shift tray is detected full .

The purpose is to accurately detect tray full for stacks of Z-folded paper, or incorrectly stacked documents.

Condition 3

Shift tray detection input check: SP6123-35 normally set to "0" (default), tray not full.