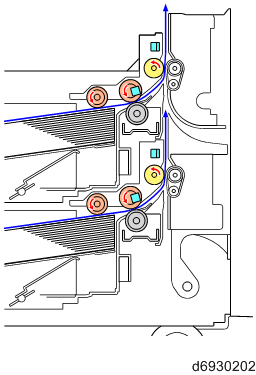

In order to feed the paper at regular intervals, there is a paper feed sensor near the pick-up roller, and this sensor is used to adjust the paper feed timing.

- The paper feed motor turns ON, and feeds the first sheet of paper.

- To prevent the next sheet from being fed, the pick-up solenoid turns ON just before the trailing edge of the first sheet passes through the pick-up roller, and the pick-up roller leaves the paper surface.

- Slightly before the trailing edge of the first sheet leaves the paper feed roller, the paper feed motor switches OFF.

However, at this time, if the paper feed sensor does not detect paper (the second sheet is not fed to the paper feed sensor position), the paper feed motor does not turn OFF. Pre-feed is performed as follows:- The pickup solenoid switches OFF, and the second sheet of paper is fed to the paper feed sensor position.

- When the trailing edge of the second sheet passes the feed roller, the paper feed motor is switched OFF. The pickup solenoid remains OFF.

- Just when the trailing edge of the first sheet passes the paper feed roller, the pickup solenoid is switched OFF, and the pickup roller is brought in contact with the paper surface.

- When the first sheet has been fed a predetermined distance by the downstream transport roller, the paper feed motor is switched ON to supply the second sheet.