- Yield Parts:

The parts mentioned in these tables have a target yield. However, the total copy/print volume made by the machine will not reach the target yield within the machine's targeted lifetime if the machine is used under the target usage conditions (ACV, color ratio, and P/J). So, these parts are categorized not as PM parts but as yield parts (EM parts). The parts with "(R)" in this table are yield parts.

Paper Feed

Item | 40K | 180K | 600K | EM | Remarks |

|---|---|---|---|---|---|

Registration Roller | C | Wipe with a damp cloth when cleaning | |||

Registration Sensor | C | Remove paper dust | |||

Transport Roller | C | Wipe with a damp cloth when cleaning | |||

Paper Feed Roller (Tray) | (R) | C |

| ||

Friction Pad (Tray) | (R) | C |

| ||

Paper Feed Roller (Bypass) | C |

| |||

Friction Pad (Bypass) | C |

|

PCDU

Item | 40K | 180K | 600K | EM | Remarks |

|---|---|---|---|---|---|

PCDU | R |

LED Optics

Item | 40K | 180K | 600K | EM | Remarks |

|---|---|---|---|---|---|

LED Lens | C |

|

Transfer/Fusing

Item | 40K | 180K | 600K | EM | Remarks |

|---|---|---|---|---|---|

Transfer Roller | (R) | C | Wipe with a damp cloth, then a dry cloth when cleaning | ||

Fusing Unit | (R) | ||||

| Image Transfer Entrance Guide (front) | C | *1 | |||

| Image Transfer Exit Guide (Rear) | C | *1 |

Paper Exit

Item | 40K | 180K | 600K | EM | Remarks |

|---|---|---|---|---|---|

Paper Exit Roller | C | Wipe with a damp cloth, then a dry cloth when cleaning | |||

Paper Exit Sensor | C | Remove paper dust |

Scanner

Item | 40K | 180K | 600K | EM | Remarks |

|---|---|---|---|---|---|

Exposure Glass | C | Use the Ricoh exposure glass cleaner | |||

SPDF Exposure Glass | C | Use the Ricoh exposure glass cleaner |

SPDF

The PM count for the following items is based on the number of originals fed:

Item | 30K | 45K | 180K | EM | Remarks |

|---|---|---|---|---|---|

Friction Pad | (R) | C | Wipe with a dry cloth when cleaning | ||

Pick-up Roller | (R) | C | Wipe with a damp cloth when cleaning | ||

Feed Roller | (R) | C | Wipe with a damp cloth when cleaning | ||

SPDF entrance roller | C | Wipe with a damp cloth when cleaning | |||

Pre-scanning roller (front side) | C | Wipe with a damp cloth when cleaning | |||

| Pre-scanning roller (rear side) | C | Wipe with a damp cloth when cleaning | |||

Exit Roller | C | Wipe with a damp cloth when cleaning | |||

Platen | C | C | Wipe with a damp cloth when cleaning | ||

| Scanning guide plate (front side) | C | C | Wipe with a damp cloth when cleaning | ||

| Scanning guide plate (rear side) | C | C | Wipe with a damp cloth when cleaning |

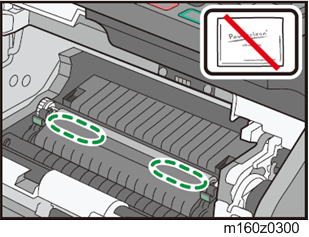

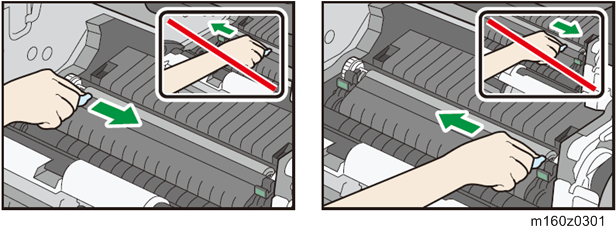

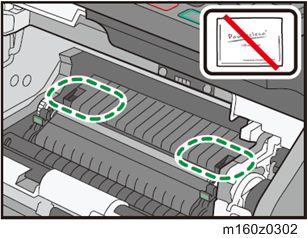

*1 When replacing the PCDU, be sure to clean the following parts;

Image Transfer Entrance Guide (front)

- Do not use the LED lens cleaner.

Remove toner and paper dust with a slightly wet cloth. Wipe off towards to the center from the green seals indicated at both sides. Do not use alcohol or detergent. Only use water, and also do not wipe off to the outside.

Image Transfer Exit Guide (Rear)

- Do not use the LED lens cleaner.

Clean toner stacked in the hollows with a slightly wet cloth. Wipe off five to six times towards to the

center from outside until stacked toner is completely wiped off.

Make sure you do not use detergent and also do not wipe off to the outside.