No Feeding 4 (Cover Interposer Tray)

Cause

When the wrong size of paper is fed, if failure to feed occurs due to paper slipping, it may be possible to improve the problem feeding by individually increasing the pressure.

This is likely to occur if:

When paper with a low coefficient of friction is fed

Solution

Add a compression spring and friction pad.

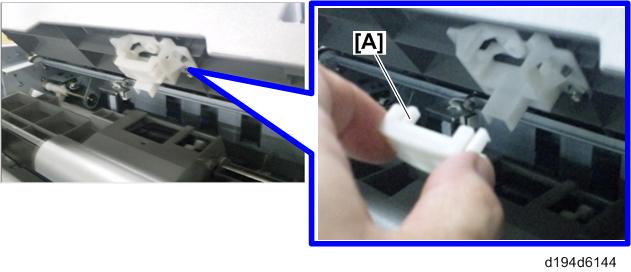

Open the tray cover and remove the plastic part [A] on the inside of the cover.

Insert the spring [A] on the inside of the plastic part you removed and re-install the plastic part.

Remove the feed belt unit [A] and stick a friction pad [B] to the upper surface of the cover.

Put the feed belt unit back as it was and load paper in the paper tray.

Visually check to make sure there is no gap between the plastic part and the friction pad after the tray finishes lifting up.